About Us

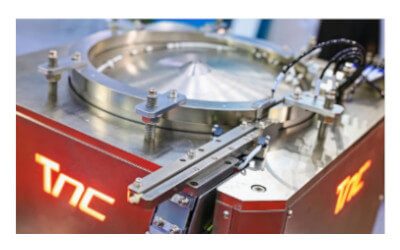

TNC Technology is a privately-owned, self-funded company specializing as bowl feeder manufacturer(振动盘) solutions, located in Penang, Malaysia.

Founded in 2007, TNC has grown tremendously over the last four years in the Malaysian industrial market, both in its customer base as well as its knowledge and skills on current trends and emerging technologies.

TNC prides itself on its dynamic environment- never content with the status quo, TNC constantly strives to challenge knowledge in technology to

bring the best bowl feeder solutions and marry the best technologies

for a given project.

Company Background

Founded in June of 2007, TNC specializes in solving your parts handling requirements in combination with our quality, reliability, service and backup.

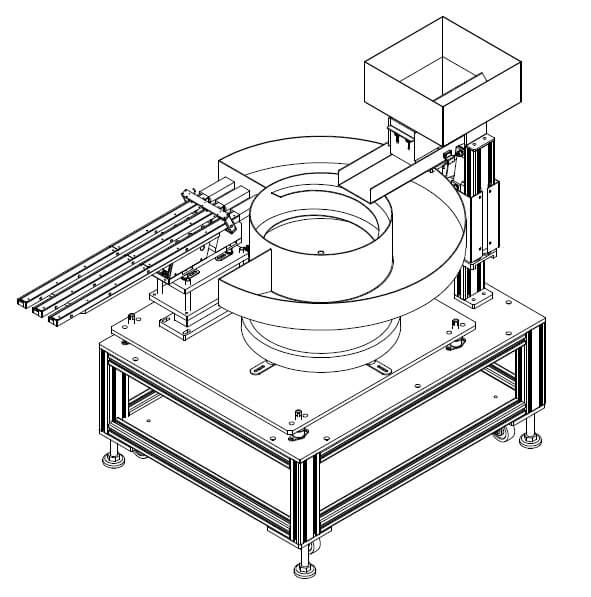

We operate in the area of specialized automation engineering, providing automatic parts handling equipment for high-volume production in semiconductor chip, pharmaceutical, electronic components, molded plastic, automotive, and metal working industries—anywhere, where there is a need to automate the handling and orientation of component parts.

Our automated equipment is custom-designed, fabricated, and built to our customers’ unique requirements. Our services include reworking and upgrading any type of part feeding systems. TNC offers comprehensive bowl feeder solutions to meet all your parts handling needs, ensuring consistent quality and reliable output for your business operations. With years of experience and a dedicated team of experts, we are committed to delivering innovative and cost-effective solutions that help our clients stay competitive in today’s fast-paced manufacturing industry.

🔧 2007 – Company Establishment

TNC Technology Sdn. Bhd. was founded in Penang as a precision engineering company specializing in custom-built bowl feeder systems. The initial workflow focused on manual design, fabrication, and assembly processes with close customer collaboration to deliver tailor-made parts-feeding solutions for local manufacturers.

🚀 2010 – Process Optimization and Market Expansion

As demand grew, TNC began standardizing its internal processes. CAD design tools and CNC machining were integrated into the workflow to improve accuracy and efficiency. The company expanded its customer base beyond Penang, serving more sectors such as electronics and automotive across Malaysia.

🛠️ 2015 – Customization & Industry Integration

In 2015, the workflow evolved to handle more complex, high-precision customization. TNC streamlined its design-to-delivery pipeline with better project tracking and introduced modular feeder components. The company also collaborated closely with clients in the semiconductor and medical industries, aligning its workflow to meet strict industry standards and QA protocols.

🌐 2020 – Digital Workflow Transformation

Faced with the COVID-19 pandemic, TNC implemented a digital workflow. Remote consultations, cloud-based documentation, and virtual design reviews became standard. Internal communications and project management were handled through tools like Zoom, WhatsApp, and cloud storage, ensuring uninterrupted support and service delivery to clients in both Malaysia and Thailand.

Why TNC?

Involvement

The client will always be in the loop.

Initiative

Challenges are approached from all angles before the final solution is implemented.

Innovation

Current trends and technologies are considered and applied where appropriate to provide the client with a long-term solution that fits.

TNC Value

Trusted

TNC’s feeder machine systems are built with high-quality components and rigorous testing procedures, ensuring consistent and reliable performance over time.

Networked Integration

TNC provides feeder machine systems that are not just automated, but also intelligent and interconnected.

Committed

TNC is committed to excellence in every aspect of its operations, from product development to customer support.

Service Hotline

Support and Consultation via:

Mon – Fri | 8:00 a.m – 6:00 p.m

You can contact us via Whatsapp at +6019 568 8826

or via our contact form

TH

TH