In Thailand’s fast-growing industrial sector, efficiency and durability are critical to maintaining seamless production processes. The aluminium bowl feeder is an exceptional solution that combines robustness, lightweight design, and precision engineering to meet the demands of various industries. These feeders are designed to enhance automation, improve productivity, and deliver long-lasting performance, making them indispensable in modern manufacturing.

At TNC Tech, we specialize in high-quality aluminium bowl feeders that cater to diverse industrial needs. Constructed from high-grade aluminium, these vibratory feeding systems provide exceptional resistance to wear and tear, making them suitable for both heavy-duty applications and delicate components. Widely used for sorting, orienting, and feeding parts with precision, aluminium bowl feeders are the popular choice for businesses looking to optimize their manufacturing processes.

This feeder set is primarily utilized in the semiconductor and electronics industries.

In Thailand’s expanding semiconductor sector, aluminium bowl feeders are essential for handling tiny, high-precision components such as microchips and wafers, ensuring accurate orientation and seamless integration into production lines.

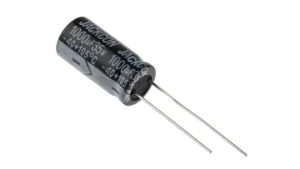

Thailand’s robust electronics manufacturing sector relies on aluminium feeders for precise handling of small, delicate components such as resistors, capacitors, and connectors.

This kind of feeder is mainly used to feed mini size, high precision and high output required products. The target field of this bowl is on semiconductor and electronics industry.

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

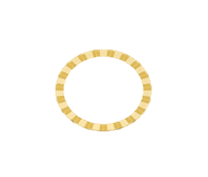

| Springwave | SOP | LED | O-ring | Capacitor | Connector Housing | Chip Resistor |

We design feeders that perfectly align with your production line, ensuring optimal compatibility and performance. Whether you need specific shapes, sizes, or feeding speeds, our tailored solutions meet the exact requirements of your operation.

Our feeders are crafted from high-grade aluminium that resists wear and tear, even in demanding industrial conditions. This ensures reliable, long-lasting performance that keeps your production running smoothly.

Based in Thailand, TNC Tech offers personalized support to address your needs quickly and effectively. From initial consultations to on-site installations and after-sales service, we ensure your feeders operate seamlessly with minimal downtime.

Our feeders are equipped with state-of-the-art vibration control systems that deliver precise and consistent feeding. These innovative features support Thailand’s transition toward Industry 4.0 by enhancing automation and production efficiency.

TNC Tech’s lightweight aluminium bowl feeders are easy to install, relocate, and maintain, helping to reduce downtime and improve overall efficiency.

Our aluminium bowl feeders feature a smooth surface finish that gently handles delicate components, preventing scratches or damage, ideal for industries with fragile or high-value parts.

TNC Tech provides aluminium bowl feeders tailored for various part sizes, shapes, and feeding needs, ensuring compatibility across industries like electronics and automotive.

Designed with energy-saving technology, our feeders minimize power consumption without compromising performance. This helps businesses reduce operational costs and align with sustainable manufacturing practices.

Constructed from high-grade aluminium, our bowl feeders offer excellent resistance to corrosion, ensuring reliable performance in Thailand’s humid tropical environment. This durability makes them ideal for industries requiring long-lasting and low-maintenance solutions.

| Sector: Semiconductor | |

| Feeding Rate: 80 pieces per min | |

| Hopper Capacity: 60 mins run time |

A major semiconductor parts supplier in Thailand experienced challenges with their aluminium bowl feeders due to incorrect part output orientation. This problem caused frequent assembly errors, leading to inefficiencies and increased production time. The supplier needed a reliable solution to improve accuracy and streamline their operations.

By switching to TNC Tech’s aluminium bowl feeders, the company achieved a 40% improvement in production accuracy. The advanced design and precision handling of TNC Tech’s feeders resolved the orientation issues, ensuring smoother assembly processes. This upgrade significantly enhanced overall operational efficiency and reduced production downtime.

Support and Consultation via:

Mon – Fri | 8:00 a.m – 6:00 p.m

You can contact us via Whatsapp at +6019 568 8826

or via our contact form