A vibratory bowl feeder is a highly effective piece of equipment used to orient and feed parts into production machinery. Through controlled vibrations, it ensures that components are presented in the correct orientation, and ready for the next stage in the manufacturing process. These feeders are widely used in industries where high-speed, accurate sorting of parts is critical. By integrating vibratory bowl feeders, manufacturers can achieve seamless automation while maintaining precision and consistency.

Thailand’s industrial growth is supported by key sectors that benefit immensely from vibratory bowl feeders:

In Thailand’s electronics industry, vibratory feeders play a key role in handling and positioning semiconductor chips with precision, ensuring accurate placement in devices.

Thailand is often referred to as the “Detroit of Asia.” To keep up with high production demands, vibratory bowl feeders streamline the handling of bolts, screws, and complex car parts, ensuring smooth assembly processes.

With the growing demand for healthcare products, vibratory feeders handle sensitive medical components with care and adherence to strict quality standards.

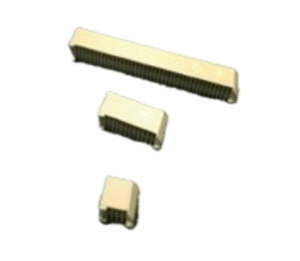

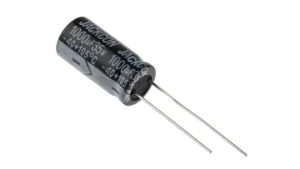

As a global hub for electronics production, Thailand requires precision-oriented solutions to handle micro-components such as chips, diodes, and capacitors. Vibratory bowl feeders excel in managing delicate parts with accuracy.

Vibratory feeders are crucial in sorting and organizing small packaging materials for logistics operations, enabling timely and accurate dispatches such as zipper beg.

This kind of feeder is mainly used to feed mini size, high precision and high output required products. The target field of this bowl is on automotive, electronics and pharmaceutical industry.

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| Needle Holder | Winged Infusion Set | Y-Piece | Resistor | Connector | Capacitor | X-Ray Steering Post |

Our vibratory bowl feeders are customizable to fit the specific needs of your production line. Whether you need feeders for intricate electronic components or heavy-duty automotive parts, we deliver solutions that align perfectly with your processes.

TNC Tech’s feeders are designed to operate with exceptional accuracy, ensuring that parts are always fed in the right orientation and position.

With a dedicated team in Thailand, we provide end-to-end support, including installation, training, maintenance, and troubleshooting. Our local presence ensures faster response times and personalized service.

Built with durable materials and advanced technology, our vibratory bowl feeders can withstand Thailand’s demanding industrial environments and deliver consistent performance over time.

Vibratory bowl feeders offer design adaptability to handle different part sizes, shapes, and materials, while seamlessly integrating with existing production systems for smooth automation.

Vibratory bowl feeders are optimized for fast feeding while maintaining precision, leading to reduced cycle times and improved productivity.

The simplified design of vibratory bowl feeders minimizes wear and tear, while easy cleaning and maintenance procedures ensure smooth, uninterrupted operations.

Vibratory bowl feeders come with intuitive controls for adjusting feeding speeds and vibration intensity, and can be integrated with modern Industry 4.0 systems for smart manufacturing.

Vibratory bowl feeders are equipped with noise-reducing features for a more comfortable workplace, while vibration-dampening materials ensure smooth and efficient performance.

| Sector: Electronics | |

| Feeding Rate: 70 pieces per min | |

| Hopper Capacity: 60 mins run time |

A leading electronics manufacturer in Thailand faced issues with incorrect part orientation in their aluminum bowl feeders. This problem caused frequent production delays and increased the need for manual adjustments. As a result, operational efficiency declined, and meeting production targets became more challenging.

After adopting TNC Tech’s vibratory bowl feeders, the manufacturer achieved a 30% increase in production speed, along with a substantial improvement in accuracy, reducing errors and streamlining their operations for greater efficiency.

Support and Consultation via:

Mon – Fri | 8:00 a.m – 6:00 p.m

You can contact us via Whatsapp at +6019 568 8826

or via our contact form