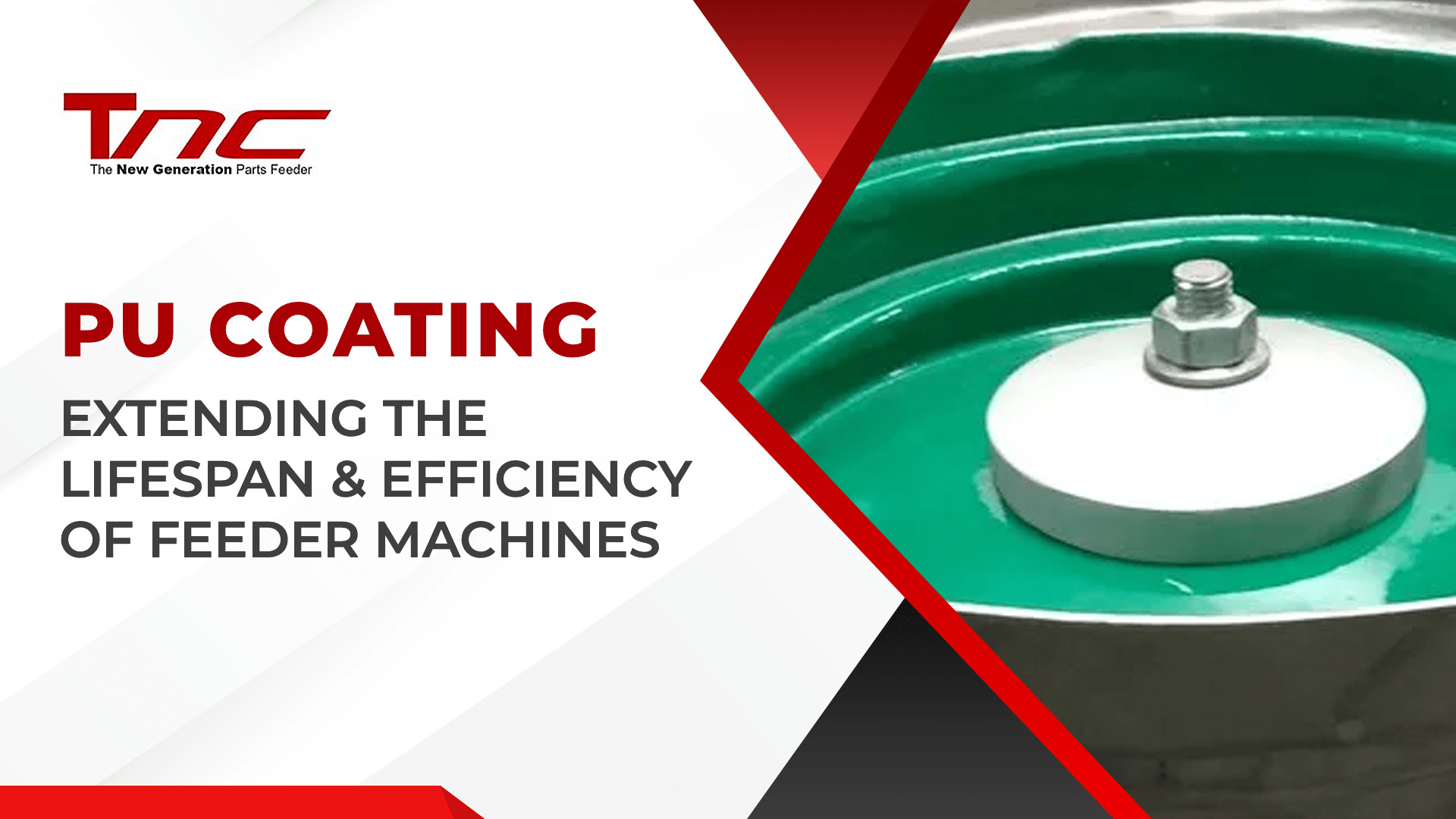

28 Nov PU Coating: Extending the Lifespan and Efficiency of Feeder Machines

In this modern day and age, machines are so ingrained in our lives like smartphones, tablets, and computers. Even manufacturing industries rely heavily on machines. Take the feeder machine for example — a critical component in every automated manufacturing process. Without it, a company would need to rely on physical labor, which increases labor costs, not to mention, introduces the risks of human error. But with an automated feeder machine, the margin for error is very minimal in part feeding systems.

But with most machines, carrying out protective measures may seem extra, but it is crucial when it comes to ensuring optimal performance and longevity. Because to be honest, we don’t want to be spending a huge amount of money, only to have the machine break down after a short amount of time right? For feeder machines, one such measure is the application of a PU coating.

What is PU Coating?

PU coating, also known as polyurethane coating, is an extremely strong coating that is both durable and versatile. You might not notice, but it is widely used everywhere. From huge vessels like ships to your regular household appliances. The coating forms a tough and resistant layer on any surface, which offers a range of benefits that will significantly enhance the performance and lifespan of equipment. And the feeder machine is no exception.

Benefits of PU Coating

- Enhanced Durability:

- Resistance to Wear and Tear: PU coating forms a tough barrier that can protect the components from constant friction and impact when going through operation process. This significantly reduces wear and tear of both the components being fed and the machine itself, thus extending the machine’s lifespan.

- Corrosion Protection: The surface coating acts as a shield against any corrosive agents, prevents rust and oxidation that can compromise the structural integrity of the machine.

- Improved Efficiency:

- Smooth Surface Finish: PU coating provides a smooth and consistent surface finish, ensuring that parts glide smoothly through the feeder mechanism. This minimizes friction and reduces the risk of part jams or damage, leading to improved efficiency and productivity.

- Reduced Noise Levels: The coating helps to dampen vibrations and reduce noise levels, creating a quieter and more pleasant working environment.

- Chemical Resistance:

- Protection Against Contaminants: PU coating is resistant to a wide range of chemicals, including oils, grease, and solvents. This is particularly important in industries where feeder machines are exposed to harsh chemicals, as the coating helps to prevent corrosion and degradation.

- Easy Maintenance:

- Simple Cleaning: The smooth surface of the PU coating makes cleaning and maintenance easier. Contaminants can be easily wiped away, reducing downtime and maintenance costs.

Choosing the Right PU Coating

When selecting a PU coating for your feeder machine, take into account the following requirements for your application:

- Types of parts that are being fed

- The operating environment or surroundings

- The desired level of protection

At TNC Technology, we can help you choose the most suitable coating application for your needs.

Conclusion

It may seem like a trivial thing just talking about a coating surface, but we assure you, an extra layer of protection is like putting on a cozy jacket during chilly days. For optimal performance and longevity, an extra PU coating can take you and your machine a long way.

Investing in this one additional step can significantly enhance the performance, durability, and efficiency of your production line. And thus, leading to increased productivity, reduced downtime, and lower maintenance costs.

TH

TH