20 Aug Why A Rotary Feeder Is the Future of Industrial Automation

Ever wondered how industries manage to keep everything running smoothly and efficiently in today’s fast-paced world? The answer often lies in innovative technologies that are increasing significantly as industries are striving to enhance efficiency and reduce downtime. Among these technologies, the rotary feeder (also known as the centrifugal feeder) stands out. It is a game-changer, revolutionizing how materials are handled and processed across different sectors.

At TNC Technology, we recognize the immense potential of rotary feeders that can transform industrial operations, and we are dedicated to providing cutting-edge feeder machine solutions that cater to the unique needs of our clients.

Understanding The Rotary Feeder

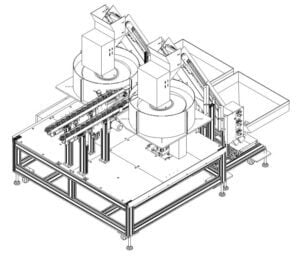

Before exploring how rotary feeders transform industrial automation, let’s first understand what they are and how they work. A rotary feeder is a feeder machine that controls the flow of bulk materials in various industrial processes. It utilizes centrifugal force through a rotating disc with pockets to efficiently move parts through a system, making them ideal for applications requiring quick and accurate part orientation and feeding.

Rotary or centrifugal feeders are designed to handle a wide range of materials, including powders, granules, pellets, and even more challenging substances like sticky or abrasive materials. Thus, making it a very versatile feeder machine. Their ability to provide a controlled and consistent flow of materials makes them indispensable in industries such as food processing, pharmaceuticals, chemicals, and more.

Achieve Peak Efficiency and Productivity

Rotary feeders enhance efficiency and productivity in industrial automation by providing consistent material flow. Unlike traditional material handling systems, inconsistencies in material flow can lead to bottlenecks, resulting in delays and reduced output. But with this feeder, these issues are effectively mitigated. The feeder’s precise control over material flow ensures a steady supply of materials to the processing unit, thereby smoothing out the entire production process.

At TNC Technology, our feeder machines can be customized to handle different types of materials, such as those with varying moisture levels or particle sizes. This level of customization helps the feeder work efficiently no matter what material it processes.

Reducing Downtime and Maintenance Costs

In industrial environments, downtime can be extremely costly, impacting both production and maintenance budgets. But with a centrifugal feeder, these issues are mitigated by offering a reliable and long-lasting solution for material handling. Their robust construction is designed to withstand harsh operating conditions, which helps to minimize the frequency of breakdowns and reduces maintenance needs.

At TNC Technology, we prioritize the durability of our industrial equipment. Our feeders are built with high-quality materials that resist wear and tear, ensuring they have a long service life. Additionally, our feeders are engineered for easy maintenance. Features like quick-release mechanisms and accessible components facilitate straightforward inspections and repairs, thereby further reducing downtime and cutting associated costs.

Versatility Across Industries

Another major benefit of rotary feeders is their adaptability across a range of industries. In the automotive industry, maintaining high standards of precision and efficiency is crucial. In the chemical industry, handling hazardous materials with precision is essential. Rotary feeders can be customized to meet the unique requirements of each sector.

For instance, in the pharmaceutical sector, these feeders play a vital role in handling and feeding vials, caps, and small medical components, ensuring that all parts are properly aligned and ready for processing. Precision and contamination prevention are critical in this industry. Rotary feeders can be equipped with features such as air-tight seals. They can also have anti-stick coatings. These features guarantee safe and accurate material handling.

At TNC Technology, we take pride in delivering bespoke feeder solutions tailored to meet the varied demands of our clients. Our expert team collaborates closely with clients to grasp their specific needs and develop feeders that achieve optimal performance in their respective industries.

Future-Proofing Industrial Automation

As industries continue to evolve, the demand for adaptable and future-proof solutions becomes increasingly important. Rotary or centrifugal feeders provide the versatility required for today’s industrial automation challenges. Their ability to manage a wide range of materials is impressive. They also offer robust durability and require minimal maintenance. This combination makes them a valuable asset in modern production settings.

At TNC Technology, we are dedicated to leading the way in industrial automation by consistently innovating and refining our feeder machine designs. We strive to deliver solutions that not only address current requirements but also set our clients up for future success.

Elevate Your Business Operations with TNC Technology

In conclusion, rotary feeders have emerged as a pivotal technology in the realm of industrial automation, offering unparalleled efficiency, accuracy, and versatility. By choosing a rotary feeder from TNC Technology, you are investing in a solution that will revolutionize your material handling processes and drive your operations to new heights of productivity and reliability.

If you are ready to take your industrial automation to the next level, contact TNC Technology today. Our team of experts is here to help you find the perfect feeder solution for your specific needs.

Contact us: +604 611 7669 | +6012 465 2181 (Malaysia) | +66 6 37540226 (Thailand)

Or email us: [email protected] or [email protected]

At TNC Technology, we are committed to helping you achieve maximum efficiency and productivity with our top-of-the-line part feeding system. Choose TNC Technology, your bowl feeder supplier in Malaysia for all your feeder machine needs!

TH

TH