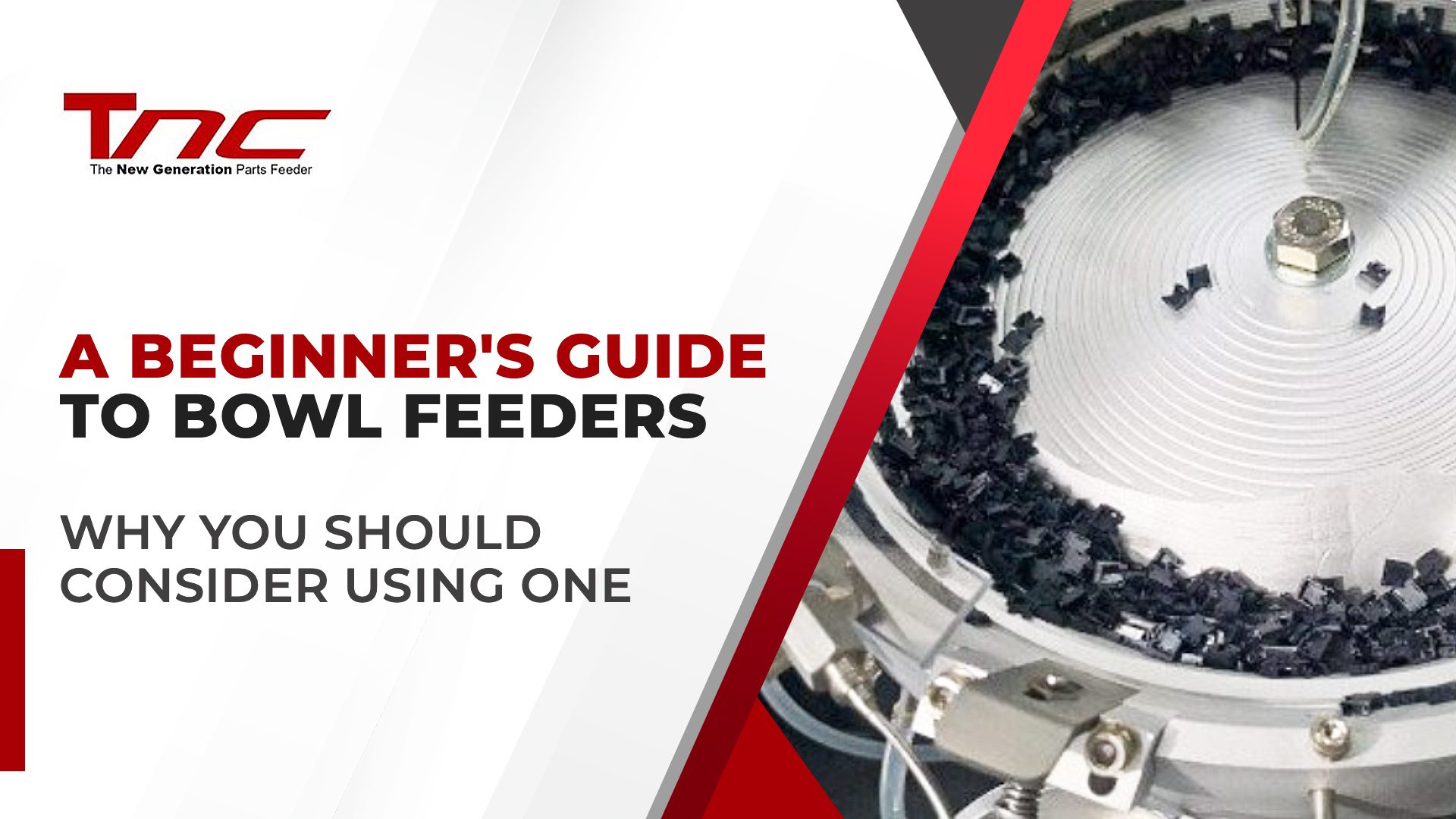

04 Oct A Beginner’s Guide to Bowl Feeders: Why You Should Consider Using One

The first day I saw a bowl feeder in action was on a field trip to a manufacturing plant back in my college days. I was gravitated toward how it effortlessly fed such tiny and minuscule components into a machine. It was like watching a super-intelligent machine working at high speed but in such a delicate manner.

Today, I’m a manufacturing engineer and I study and build bowl feeder machines in TNC Tech. I’ve always been drawn to automation, trying to understand how these machines work. So when I learned about the functions and how much benefit a bowl feeder can bring, I was hooked. If you’re new to the world of automation and manufacturing, or just simply looking for ways to improve your operation, you might be intrigued as to how these machines work. Today let me try to explain how a bowl feeder works.

Let’s break it down.

What is a bowl feeder?

Think of it as a high-tech buffet for your machines. There’s a lineup of various components, just like how you would see the assortment of dishes at a buffet. A bowl feeder, also known as a part feeding system, is quite the efficient tool when it comes to sorting components. So there’s this device that holds a supply of these small parts and delivers them into a machine one by one. It’s like having a dedicated server for your manufacturing process.

So imagine a swirling and vibrating bowl filled with small components. As the bowl is spinning, the server will sort out, orient, and feed the parts into a machine at a steady pace. It’s like a miniature factory within a factory!

So, how does it work?

Load the bowl: An operator simply dumps a bunch of parts into the bowl.

The magic happens: As the bowl vibrates, the system sorts and orients the parts based on their shape and size.

Feeding time: The system feeds the parts into a linear track or nest, where a machine or robot can pick them up.

It’s a simple yet ingenious system that has revolutionized manufacturing processes.

Why should you use a bowl feeder?

Increased Productivity: Imagine having a constant stream of parts ready to be processed. No more manual feeding, no more downtime. Your machines can run at full capacity, and thus your production output will skyrocket.

Improved Quality: Bowl feeders ensure that parts are fed consistently and accurately, reducing the risk of defects or errors. Your products will be of higher quality, and you’ll have fewer headaches down the line.

Reduced Waste: Fewer errors mean less waste. You’ll save money on materials and reduce your environmental impact. It’s a win-win for everyone.

Enhanced Safety: Manual handling of small parts can be hazardous. With a bowl feeder, you’re reducing the risk of injuries and creating a safer workplace for your employees.

Is a bowl feeder right for you?

If you’re dealing with small, loose parts and looking to improve your manufacturing process, then a bowl feeder might be just what you need. They offer versatility and serve a variety of industries, ranging from electronics to automotive.

Ready to take the plunge?

If you’re convinced that a bowl feeder is the right solution to boost your efficiency and productivity, then it’s time to take the next step. TNC Tech is here to discuss your specific needs and explore which bowl feeder options are available for you. Our experts can help you through the entire customization process and find the perfect solution to streamline your operations and maximize your output.

Conclusion

I hope this blog post has given you a better understanding of the benefits of using a bowl feeder. It’s a simple yet powerful tool that can significantly improve your manufacturing operations. So, why wait? Consider adding a bowl feeder to your arsenal and watch your productivity soar.

TH

TH