12 Aug How a Vibratory Bowl Feeder Can Enhance Your Production Efficiency

Keeping things running smoothly and reliably is key for many manufacturing industries. At TNC Technology, we understand the significance of optimizing the production process to achieve maximum output while still maintaining high quality. And one of the key elements in achieving these goals is the feeder vibration mechanism in the vibratory bowl feeder. In this post, we will dive into how this feeder machine can enhance production efficiency and also explore the benefits it can offer in automated assembly lines.

What is a Vibratory Bowl Feeder?

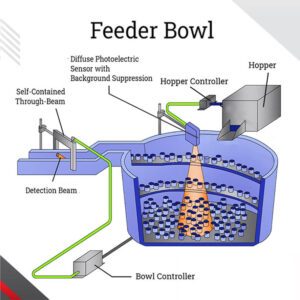

A vibratory bowl feeder is an efficient yet versatile feeder machine designed to feed individual components into an assembly line. Featuring a stainless steel bowl with a spiral track that aligns parts into a specific orientation, it guarantees a steady and regulated flow of components. The bowl will vibrate, causing parts to move along the guided track and into the desired position. This mechanism is essential for preserving the efficiency of automated assembly lines.

Enhance Production Efficiency with a Vibratory Bowl Feeder

How A Feeder Bowl Looks Like

Consistent and Reliable Supply

Primarily, the vibratory bowl feeder ensures a steady and dependable flow of components to the assembly line. This reliability is crucial, as it eliminates the risk of downtime caused by inconsistent feeding. Thereby it guarantees a smooth and efficient production process, driven by optimal feeder vibration.

High-Speed Feeding Applications

Additionally, they are designed for high-speed feeding applications, making them perfect for industries needing fast production rates. By ensuring a consistent flow of parts, it can greatly boost the throughput of your assembly line. This improvement in throughput results in higher production volumes and shorter cycle times.

Precision and Accuracy

Moreover, precision and accuracy play a very important part in automated assembly lines. A vibratory bowl feeder stands out in this area by consistently orienting and feeding parts in the required orientation. Thanks to controlled feeder vibration, this accuracy reduces errors and improves the overall quality of the final product.

Versatility

This feeder machine is highly versatile. They are able to handle a wide range of component shapes and sizes. This flexibility allows manufacturers to utilize just one feeder for multiple products, thus reducing the need for numerous machines and saving up valuable floor space. Their rapid changeover capabilities also facilitate quick adjustments to new production demands, thereby boosting overall efficiency.

Labor Cost Savings

Lastly, an automated vibratory bowl feeder streamlines the feeding process, minimizing the need for manual work. This reduction leads to significant labor cost savings, allowing operators to focus on other tasks such as quality control and machine maintenance, rather than manually feeding components into the assembly line which can be quite tedious as well.

Versatile Applications of Vibratory Bowl Feeders Across Industries

Vibratory feeders are indispensable in a variety of industries due to their efficiency and precision in handling and orienting materials. Here’s how they contribute to different sectors:

Semiconductor Industry

In the semiconductor industry, vibratory bowl feeders are essential for handling and positioning delicate semiconductor chips with precision. This careful management ensures that chips are accurately placed into electronic devices, which is key for the dependable performance of high-tech equipment.

Automotive Industry

For the automotive industry, vibratory bowl feeders handle essential components such as bolts, screws, and other small parts. They make the assembly process smoother by ensuring these components are fed accurately and efficiently. This is vital for maintaining the quality and reliability of automotive assemblies.

Pharmaceutical Industry

In the pharmaceutical sector, vibratory feeders also plays a critical role in the packaging and processing of products. They help uphold high standards of hygiene and precision, making it crucial for maintaining the integrity and safety of pharmaceutical goods throughout production.

Electronics Industry

Vibratory bowl feeders are ideal for feeding small electronic components within the electronics industry. Their ability to handle delicate electronic components with accuracy ensures reliable and efficient assembly processes, essential for producing high-quality electronic devices.

Packaging Industry

The packaging industry benefits from these machines in sorting and feeding packaging materials. Streamlining these processes enhances efficiency and consistency in packaging operations, which is key for meeting production demands and maintaining product quality.

Conclusion

Incorporating a vibratory bowl feeder into your automated assembly line can yield significant benefits, from enhancing production efficiency to improving product quality and reducing costs. At TNC Technology, top-of-the-line feeder machines designed to meet the specific needs of your manufacturing process are our specialty.

If you are looking for reliable and efficient feeder machine solutions, look no further than TNC Technology. Contact us today to learn more about our high-speed centrifugal feeders, aluminium bowl feeders, and vibratory bowl feeders. Let us help you find the best bowl feeder Malaysia solution for your application.

Contact us: +604 611 7669 | +6012 465 2181 (Malaysia) | +66 6 37540226 (Thailand)

Or email us: [email protected] or [email protected]

At TNC Technology, we are committed to helping you achieve maximum efficiency and productivity with our top-of-the-line part feeding system. Choose TNC Technology for all your bowl feeder Malaysia needs!

TH

TH