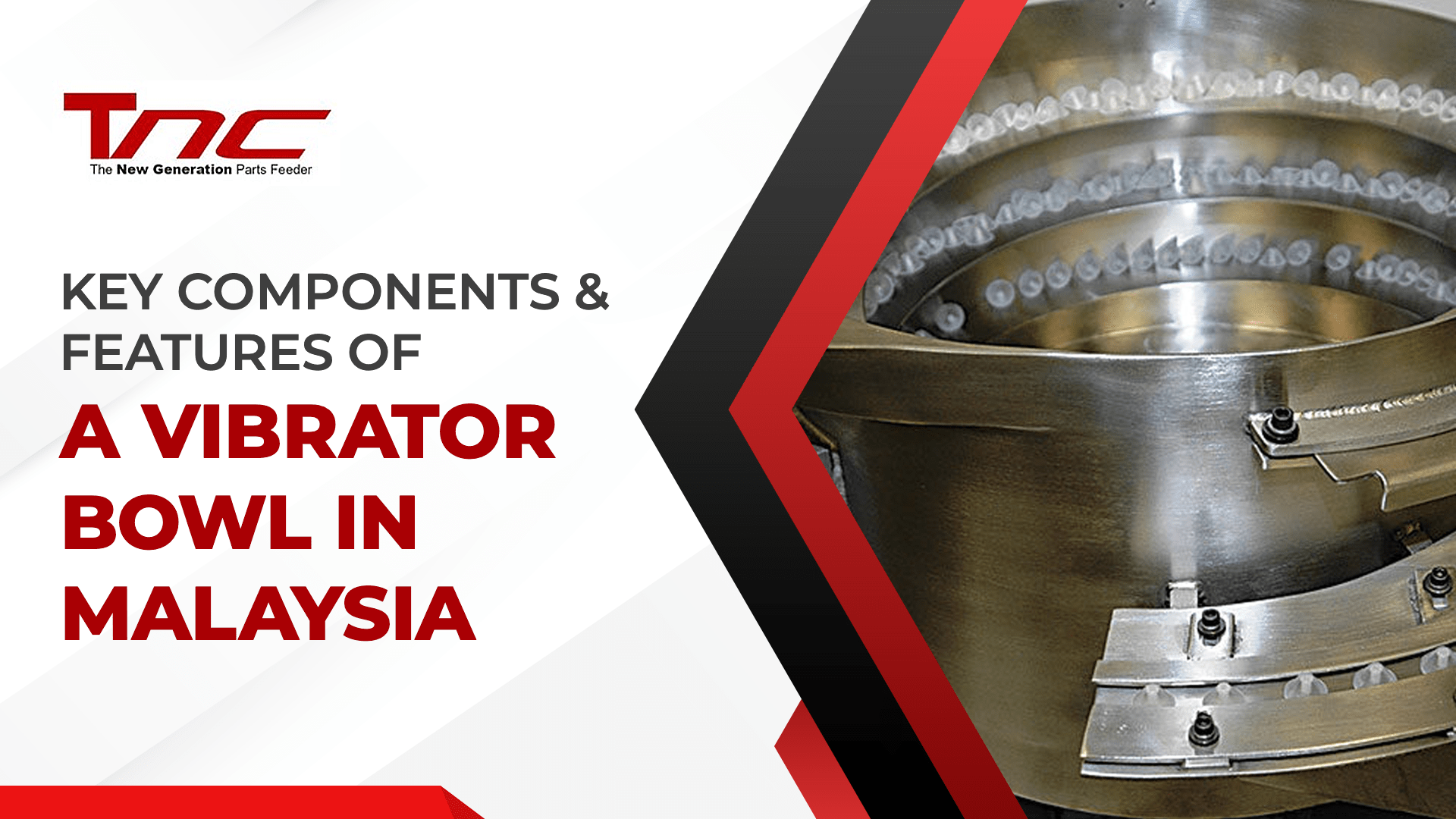

31 Dec Key Components & Features of A Vibrator Bowl in Malaysia

Vibratory feeders are essential components in many manufacturing processes, particularly in industries like electronics, automotive, and pharmaceuticals. In Malaysia, where manufacturing plays a significant role in the economy, understanding these systems is crucial for optimizing production lines.

Key Components of a Vibratory Bowl Feeder

At the heart of any part feeding system lies the vibratory bowl feeder. This component is responsible for receiving and transporting parts along a spiral track. The bowl’s design is critical, as it must accommodate the specific size and shape of the parts while ensuring smooth and consistent movement.

Beyond the vibrator bowl, several other components contribute to the overall functionality of the system:

- External Tooling: These mechanisms manipulate and orient parts before they are presented to the next stage of the assembly process.

- Linear Track: This component delivers oriented parts to the subsequent steps in the assembly line, ensuring a smooth and uninterrupted flow.

- Controls and Photo-Optics: These systems monitor and regulate the movement of parts through the feeder, ensuring optimal performance and minimizing errors.

- Machine Base: A stable and robust base is essential for supporting the entire system and ensuring smooth operation.

- Pre-Feeder: This component supplies parts to the vibrator bowl at a consistent rate, maintaining a steady flow throughout the system.

- Shuttle or Escapement Mechanisms: These optional components can be added to isolate specific parts for downstream processes.

Benefits of Using A Vibrator Bowl in Malaysia

- Increased Productivity: By automating part feeding, vibratory feeders significantly enhance production speed and efficiency.

- Improved Quality: Consistent part orientation and feeding minimize errors and improve the overall quality of the finished product.

- Reduced Labor Costs: Automated feeding reduces the need for manual labor, leading to significant cost savings.

- Enhanced Safety: Eliminating manual part handling minimizes the risk of workplace injuries.

- Versatility: Vibratory feeders can be adapted to handle a wide range of part sizes and shapes, making them suitable for various applications.

Choosing the Right Vibratory Feeder System

Selecting the appropriate vibratory feeder system for your specific needs requires careful consideration of factors such as:

- Part size, shape, and weight

- Production volume requirements

- Integration with existing production lines

- Budget constraints

- Maintenance requirements

By carefully evaluating these factors and working with experienced suppliers, manufacturers in Malaysia can select and implement vibratory feeder systems that optimize their production processes, improve efficiency, and enhance their overall competitiveness.

Conclusion

Vibratory feeders are indispensable tools for modern manufacturing in Malaysia. By understanding the key components and their functions, manufacturers can leverage these systems to improve productivity, enhance quality, and achieve significant cost savings.

TH

TH